Section 7. Modernization of Facilities

Item 3. Facility Modernization Five-year Plan-Towards a System for Producing 3,000 Vehicles per Month

- Repair and maintenance of existing equipment and machinery

- Automation of machine tools and having one person be in charge of several machines

- Streamlining transport

- Results from first half of the Production Facility Modernization Five-Year Plan

- Results from second half of the Production Facility Modernization Five-year Plan

- Death of Founder Kiichiro Toyoda and Risaburo Toyoda

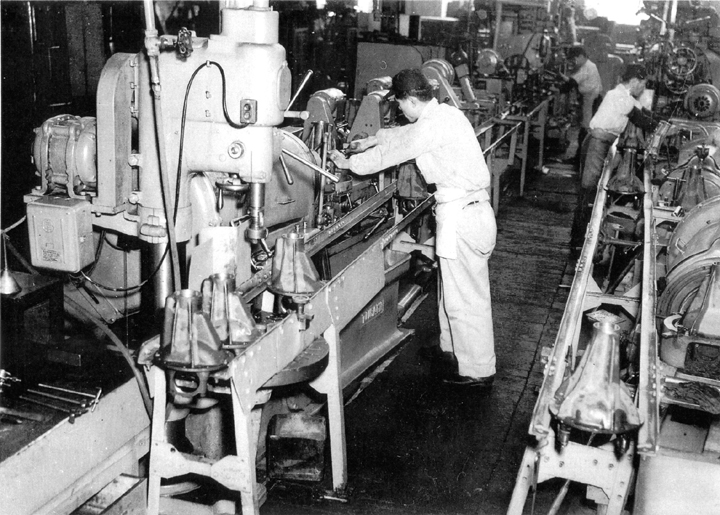

Automation of machine tools and having one person be in charge of several machines

While equipment and machinery was restored, automation of machine tools was also implemented. Specific automation measures included the introduction of automatic delivery equipment using plate cams and automatic shut-down devices using micro-switches. This was technology developed as a result of observations made in the United States.

The automation of equipment was an essential condition for putting one employee in charge of several machines, an idea proposed by Koromo Plant Machining Plant General Manager Taiichi Ono.

General Manager Ono had been an engineer at Toyoda Boshoku Corporation where he observed a single worker operating up to 20 automatic looms. He believed that it was inefficient for each worker to operate only one machine.

The engine plant and powertrain plant under the machining division of Koromo Plant had been separate organizations, but they were integrated in August 1949 to establish a single machinery plant. At that time, investigations of having one worker operate several machines began with General Manager Ono playing a central role.

Having one worker operate multiple machines was premised on the automation of machine tools, for example, in the use of automatic shut off and automatic parts feeds. It would be possible if processes could consist of automatic multi-cut lathes, automatic special-purpose machines using various types of power units, and so on. However, the costs required for automation were considerable, and the necessary returns could not be guaranteed with small-scale production.

Equipment was converted into simple automatic machinery by installing simple cam-feed mechanisms and micro-switches and giving the equipment automatic feed and automatic shutdown functions. By introducing this type of automation, it became possible for a single worker to operate multiple machines, dramatically raising work efficiency.

When one worker was responsible for multiple machines, there was no time for the workers to sharpen the machinery tools (cutting tools), and it became necessary to specialize tool sharpening. As a result, a centralized sharpening system was introduced at all machine plants in November 1951, and the Central Tool Department performed tool collection, sharpening, and delivery.

- Repair and maintenance of existing equipment and machinery

- Automation of machine tools and having one person be in charge of several machines

- Streamlining transport

- Results from first half of the Production Facility Modernization Five-Year Plan

- Results from second half of the Production Facility Modernization Five-year Plan

- Death of Founder Kiichiro Toyoda and Risaburo Toyoda