Toyota Production SystemA production system based on the philosophy of achieving the complete elimination of waste in pursuit of the most efficient methods

Toyota Motor Corporation's Toyota Production System (TPS) is a way of making things that have become known and studied worldwide.

It is based on the premise of making work easier for workers. The objective is to thoroughly eliminate waste and shorten lead times to deliver vehicles to customers quickly, at a low cost, and with high quality. This production system is pursued in all areas of Toyota Motor Corporation, including vehicles and services, and all employees implement daily incremental kaizen.

The Two Pillars of TPS

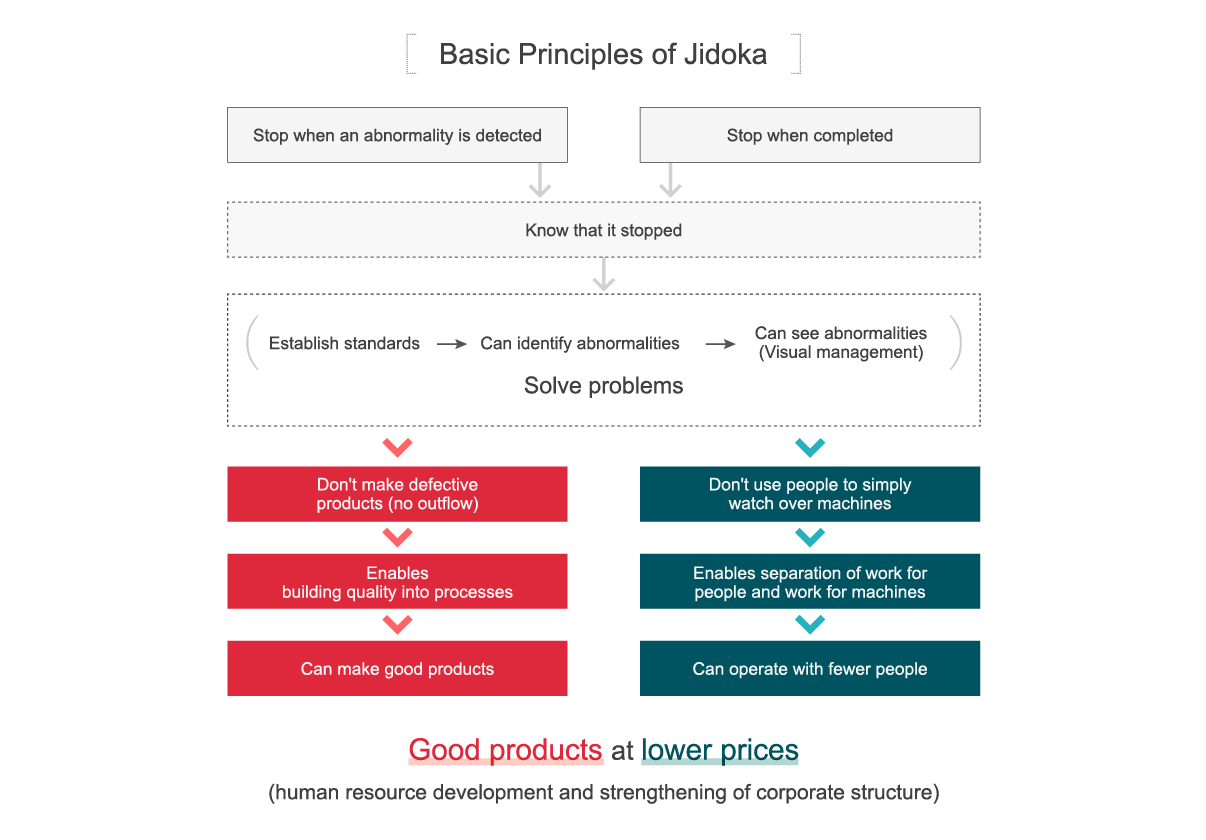

The basic philosophy of the Toyota Production System is based on two pillars. The first pillar is jidoka―which can be loosely translated as "automation with a human touch"―based on the concepts of stopping immediately when abnormalities are detected to prevent defective products from being produced and improving productivity to eliminate the need for people to be simply watching over machines. The second pillar is Just-in-Time, based on the concept of synchronizing production processes―linking all plants and their production processes in a continuous flow―by making only what is needed, when it is needed, and in the amount needed.

These two pillars enable the production of vehicles that satisfy customer requirements quickly, at a low cost, and with high quality.

Jidoka

Jidoka in the TPS is "automation with a human touch," where human wisdom is added to automation. Human wisdom means that when an abnormality occurs, such as a machine or equipment abnormality, quality abnormality, or a work delay, the machine or equipment can detect the abnormality and stop automatically, or the operator can stop the line by pulling the stop cord themselves. This eliminates the outflow of defective products while also making it possible to build quality into processes by clearly detecting abnormalities and preventing them from recurring. Furthermore, having the ability to stop when an abnormality is detected means that machines and equipment no longer need to be watched over, saving labor by reducing working hours.

To create these kinds of machines, it is necessary to first be able to do the work smoothly and correctly by hand, determine abnormalities in the work, and replace those operations with machines. In other words, rather than starting with a machine from the beginning, you must first try doing it thoroughly by hand, implement kaizen, eliminate waste, inconsistencies, and unreasonable requirements―known respectively in Japanese as muda, mura, muri―and make it possible for anyone to do the work. You must then make it possible to detect abnormalities in the work and build that into the actual machines. These incremental efforts lead to a production line that is high-quality, low-cost, flexible, and easy to maintain.

This implementation of kaizen on work is the bedrock of jidoka. It doesn't matter how much machines, robots, or IT excel; they can't evolve any further on their own. Only humans can implement kaizen for the sake of evolution. In other words, craftsmanship is achieved by discovering the basic principles of manufacturing through manual work and then applying them on the production line to steadily implement kaizen. This cycle of kaizen in both human skills and technologies is critical for taking on the challenge of new technologies and construction methods. Human wisdom and ingenuity are indispensable to delivering ever-better cars to customers. Going forward, we will maintain our steadfast dedication to constantly developing human resources who can think independently and implement kaizen.

-

-

- When equipment stops, the andon (problem display board) lights up to notify workers of the abnormality. People need only respond when there is an abnormality, thus eliminating the need for a person to watch over the equipment.

-

-

-

- Even on a line without equipment, the andon is set to light up when the stop cord is pulled so that workers can call the person in charge when there is an abnormality, such as poor quality or delay in human work.

-

Just-in-Time

- Making only what is needed, when it is needed, and in the amount needed

- Fulfilling orders from customers as quickly as possible

A car is made up of more than 30,000 parts. These parts are made not only by Toyota but also at the plants of many of our business partners. All plants must work with complete synchronization to make the vehicles quickly and without waste. All adhere to the following principles of Just-in-Time to achieve synchronized production: 1) Only make what is needed by the customer, when it is needed, and in the amount needed; 2) Don't allow goods and information to be held up during production; 3) Make them at the pace at which they're sold. It would take many months to fulfill a customer's order if all the parts were made only after receiving it. To avoid that, the minimum number of parts needed are stocked in advance on the vehicle assembly line so that a car can be built as soon as the order is received. The preceding process has a store of finished products from which the next process can pick up the parts that it needs. The preceding process is also stocked in advance with the minimum number of parts needed to re-make parts picked up by the next process before the next pick-up, allowing it to immediately replenish whatever was picked up. Having all processes engaged in this loop achieves wasteless production where we only make what is needed, when it is needed, and in the amount needed to fulfill customer orders and ensure that only sellable items are produced.

The continuous pursuit of these two pillars of the TPS are the wellsprings of Toyota's competitive strength and unique advantages. We will develop human resources throughout Toyota who put this philosophy into practice to make ever-better cars that will be cherished by customers.

Origin of the Toyota Production System A production system fine-tuned over generations

Roots of the Toyota Production System

The Toyota Production System (TPS), which is based on the philosophy of the complete elimination of waste in pursuit of the most efficient methods, has roots tracing back to the automatic loom invented by Sakichi Toyoda, the founder of the Toyota Group. TPS has evolved through many years of trial and error to improve efficiency based on the Just-in-Time concept developed by Kiichiro Toyoda, the founder of Toyota Motor Corporation.

At the root of this is Sakichi Toyoda's idea of "doing things for others." As he sought something he could do that would benefit the world, he focused on making things easier for his mother, who worked late into the night operating a manual loom. The automatic loom that he invented not only automated work that used to be performed by hand but also built the capability to make judgments into the machine itself. By eliminating both defective products and the associated wasteful practices, Sakichi succeeded in rapidly improving both productivity and work efficiency. This is where the concept of jidoka was born.

Kiichiro Toyoda advocated Just-in-Time based on this strong conviction: "A complete car cannot be built if even one part is missing. Coordinating this is no small task. However, without this control, we could have a mountain of parts and still not be able to build a car. No amount of money will suffice if we don't think of a unique way to organize these tens of thousands of parts."

Via the philosophies of Daily Improvements and Good Thinking, Good Products, TPS has evolved into a world-renowned production system. Even today, all of Toyota is implementing kaizen to TPS day and night to ensure its continued evolution.

We carry on TPS around the world with a strong desire to contribute to the enrichment of society and the nation, which has continued since the days of Sakichi and Kiichiro.

-

-

- Sakichi Toyoda (1867-1930)

- Toyoda Power Loom equipped with a new weft-breakage automatic stopping device (developed in 1896)

World's first automatic loom with a non-stop shuttle-change motion, the Type-G Toyoda Automatic Loom (developed in 1924)

-

-

-

- Kiichiro Toyoda (1894-1952)

- Drawing on his experience of introducing a flow production method using a chain conveyor into the assembly line of automatic looms (completed in 1927) with a monthly production capacity of 300 units, Kiichiro Toyoda also introduced this method into the body production assembly line at Toyota Motor Co., Ltd.'s Koromo Plant (present day Honsha Plant), completed in 1938.

-

-

-

- Eiji Toyoda (1913-2013)

- By ensuring thorough implementation of jidoka and the Just-in-Time method, Eiji Toyoda increased workers' productivity by adding value and realized the Toyota Production System, which enabled Toyota to compete head-on with companies in Europe and the U.S.

-

-

-

- Taiichi Ohno (1912-1990)

- With strong backing from Eiji Toyoda, Taiichi Ohno built the foundation of the Toyota spirit of monozukuri by helping establish the Toyota Production System, and creating the basic framework for the Just-in-Time method.

-

![[Special Lecture] Akio Toyoda's 14-year battle | Steadfast Reforms: Lessons from TPS](https://global.toyota/pages/news/images/2024/01/22/toyotatimes_01/20240122_02_t_w610_en.jpg)