Section 5. Wartime Research and Production

Item 10. The Automotive Industry Under a Controlled Economy

Control of the parts manufacturing industry

When the Model AA passenger car and Model GA truck were announced in September 1936, Japan's parts industry was undeveloped and imported electrical equipment, carburetors, speedometers, spark plugs, and other components were used. As previously explained, the Automotive Department of Toyoda Automatic Loom Works began internal development of electrical equipment and rubber parts when it was designated a licensed company under the Automotive Manufacturing Industries Law that same month and it became obligated to use domestic parts. At the same time, Eiji Toyoda and Iwao Tatematsu investigated parts plants for machined, stamped, and forged parts and began developing suppliers one by one.

The Ministry of Commerce and Industry determined that improving the quality of parts was essential for raising the quality and performance of automobiles and on March 11, 1938 adopted the High-Quality Automobile Parts and Automobile Materials Certification Regulations as a measure to support the development of the automobile parts manufacturing industry. Initially, the parts of 30 companies were certified as high quality automobile parts, and the certified companies established the Certified Automobile Parts Industry Association. The association was granted preferential treatment, and the number of members steadily increased over the years. In addition, parts manufacturers that were not able to obtain certification (with annual production value of at least 120,000 yen) established regional automobile parts industry associations in Tokyo, Osaka, Nagoya, and Yokohama. On July 1, 1938, the National Automobile Parts Industry Federation was established with the participation of the Certified Automobile Parts Industry Association and the regional associations. When the Materials Mobilization Plan mentioned above came into effect, these automobile parts industry associations became the distribution organizations for materials used in parts manufacturing. Also, the Japan Auto Parts Industries Association was established as a subsidiary organization to the Automobile Control Association created in 1941, and the National Automobile Parts Industry Federation and related associations were disbanded.1

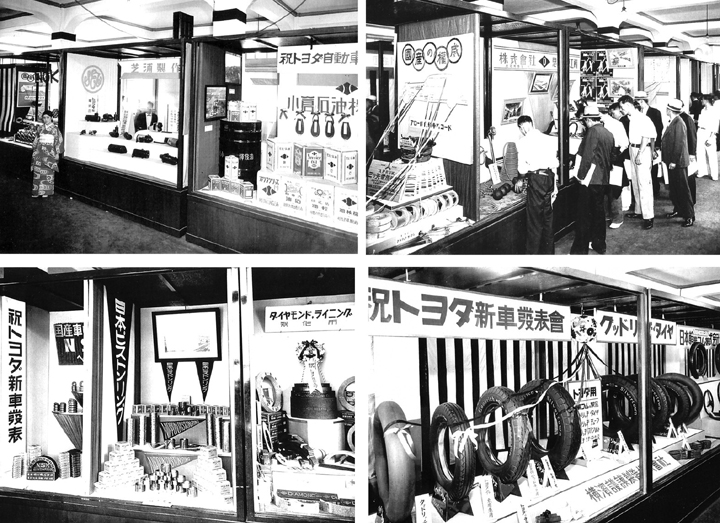

As the parts industry was developed and organized, the parts used in Toyota vehicles steadily shifted from imports to domestic products.2 Amidst the control of both the volumes and prices of raw materials, Toyota Motor Co., Ltd. held the first meeting of the Toyota Subcontractors' Round Table Conference (Domestic Automobile Subcontractors Industry Formation Round Table Conference) on November 7, 1939 at the Kuramae Industrial Hall in Shinbashi, Tokyo as a forum for exchanging ideas and opinions with representatives of cooperating plants. Kiichiro Toyoda was ill and could not attend the conference, and instead, Shuji Ono, manager of the Purchasing Section, explained-based on a manuscript submitted by Kiichiro-that the Just-in-Time concept planned to be introduced in conjunction with the start of operations at the Koromo Plant was not possible because of the control of raw materials.3

This conference was named the Kyoryokukai and became a regular event. Later, a close relationship developed between Toyota Motor Co., Ltd. and the Kyoryokukai, and in December 1943, its purpose as an organization to foster good relations was strengthened and it was relaunched as the Kyohokai4 (a voluntary organization of parts suppliers).