Section 7. Modernization of Facilities

Item 3. Facility Modernization Five-year Plan-Towards a System for Producing 3,000 Vehicles per Month

- Repair and maintenance of existing equipment and machinery

- Automation of machine tools and having one person be in charge of several machines

- Streamlining transport

- Results from first half of the Production Facility Modernization Five-Year Plan

- Results from second half of the Production Facility Modernization Five-year Plan

- Death of Founder Kiichiro Toyoda and Risaburo Toyoda

Streamlining transport

Managing Director Eiji Toyoda and Managing Director Shoichi Saito focused on streamlining transport from the time that they returned from training at Ford.1 The Transport Countermeasures Committee was established in early 1951 to investigate, conduct research on, and improve transport including the establishment of transport control systems, and improving transport equipment and adopting standards to raise transport efficiency.

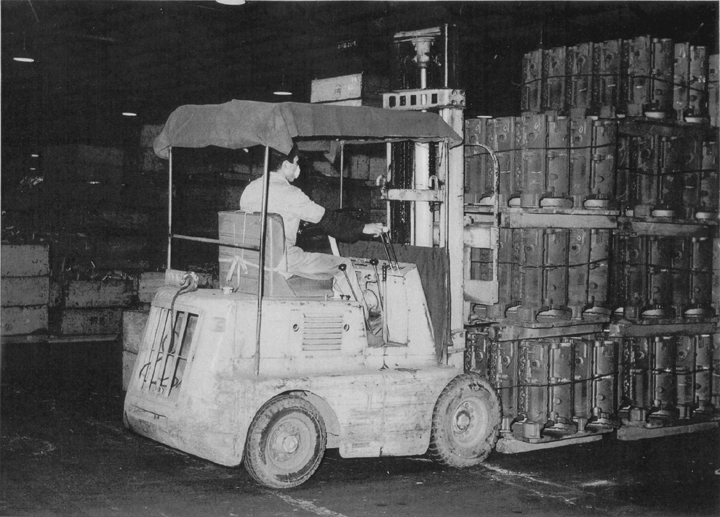

In place of the hand carts, hand trucks, trucks, and so on used within the plants, forklifts and truck trailer trains (towing tractors) were adopted. At the same time, pallets and box pallets used for transport were standardized. In addition, electric hoists and various types of conveyors were extensively installed to raise work efficiency.

In July 1951, electric forklifts (FHL-1) manufactured by Shinko Electric Co., Ltd. were introduced between the casting plant and No. 1 machining plant to transport model B engine cylinder blocks, cylinder heads, and camshafts. When using hand carts and hand trucks, it took five workers (634.05 man-hours per month) to transport 1,000 each of these three products, but after the introduction of the forklifts, one worker was able to perform the same work in 87.5 hours. This of course led to cost reductions, and when depreciation, maintenance expenses, and labor costs are included, the monthly savings were 52,166 yen.

Improved Model SB small trucks with shortened beds were used as towing trucks to tow multiple carts loaded with parts and deliver the parts to the various processes. By specifying the operating times of the towing tractors, it was possible to deliver the necessary parts to the required locations at the time needed, and the trucks became an important means of implementing the Just-in-Time System.

Later, Shinko Electric Co., Ltd. and other companies sold forklifts equipped with Toyota Motor Co., Ltd. Model S engines (950 cc)2, and in response, Toyoda Automatic Loom Works, Ltd. developed and manufactured the Model LA forklift using the same engine starting in March 1956. Toyota Motor Sales Co., Ltd. handled sales of the forklift.

The business of selling forklifts and other industrial vehicles expanded rapidly for Toyota Motor Sales Co., Ltd. The business became a division of Toyota Motor Corporation after the merger of Toyota Motor Co., Ltd. and Toyota Motor Sales Co., Ltd., and in December 2000, it was transferred to Toyota Industries Corporation. Manufacturing and sales were integrated, and Toyota L&F Company became an internal company of Toyota Industries Corporation in 2001.

- Repair and maintenance of existing equipment and machinery

- Automation of machine tools and having one person be in charge of several machines

- Streamlining transport

- Results from first half of the Production Facility Modernization Five-Year Plan

- Results from second half of the Production Facility Modernization Five-year Plan

- Death of Founder Kiichiro Toyoda and Risaburo Toyoda