March 30, 2021

Toyota Frontier Research Center Develops Decorative Films for Photovoltaic Modules: Automotive Painting Technologies to Promote the Use of Solar Power

The Toyota Motor Corporation Frontier Research Center (Toyota) and Nippon Paint Automotive Coatings Co., Ltd. (NPAC) have jointly developed decorative films for photovoltaic modules. The films1 make use of automotive painting technologies to add color to the modules. Since March 12, 2021, Toyota and NPAC have been working with F-WAVE Company Limited (F-WAVE) on a series of verification tests at F-WAVE’s Kumamoto Factory. The films are applied to F-WAVE’s mass-produced flexible, lightweight photovoltaic modules, and the aim is to assess different types of durability, power generation, and design. An overview of the decorative films and verification tests appears below.

1. Decorative films

1-1. Development background

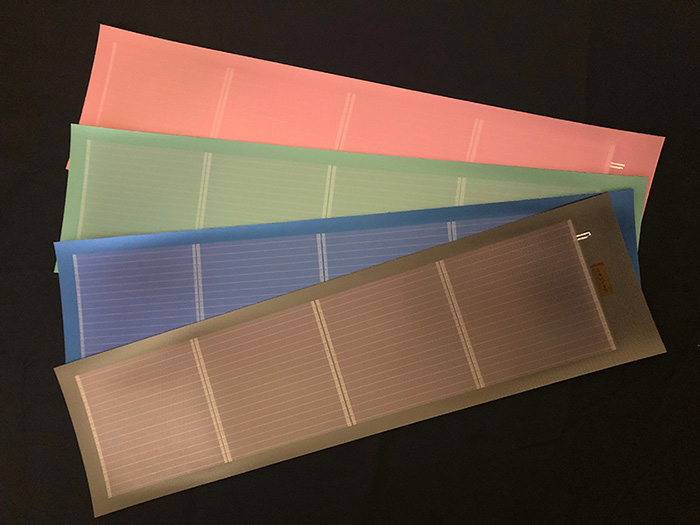

Solar energy is renewable. As such, it is becoming increasingly widespread: photovoltaic modules are being installed in a widening range of places, from rooftops and walls to various forms of mobile devices. Previously, photovoltaic modules were available only in the colors of black and dark blue. But now, there is a growing need for the modules to fit in better with their surroundings. Ordinarily, covering photovoltaic modules in film would prevent sunlight from entering its solar cell, and so it would not generate any power. But the decorative films developed by Toyota and NPAC allow most sunlight to enter. In that way, photovoltaic modules can be decorated in various colors such as pink, blue and green, without resulting in a significant loss in the amount of power generation.

1-2. Color-application method

Humans perceive color when light hits an object, is reflected from the object, and then strikes photoreceptor cells on the retina. The color pigments used in the decorative films developed by Toyota and NPAC reflect only specific wavelengths of light: they are perceived by humans as having color, but they allow most sunlight to pass through. When the decorative films are applied to photovoltaic modules, they decorate the modules while retaining the cells’ ability to generate power.

The decorative films contain semitransparent color pigments developed originally for automotive painting, which reflect specific wavelengths with narrow range of light. The pigments have scale-like shapes. To achieve uniform color application, the pigments are arranged so that they all point in the same direction. The pigments also have to maintain a uniform thickness of just a few micrometers. The decorative films make use of technologies developed to produce resin films for the decorative wrappings for automobile exteriors. Pigments are suspended in transparent resin, and the resin is then stretched using a sharp blade to ensure that the pigments point in the same direction when the film is produced. This results in a decorative film with uniform color on the entire surface of it.

By selecting the appropriate pigments, the decorative film can be produced in a wide range of colors. Through incorporating printing technologies into the production process, it is also possible to create films with various patterns, such as wood-grain, brick, and camouflage patterns.

1-3. Power generation capacity

The decorative films developed by Toyota and NPAC allow sunlight to enter the photovoltaic modules and generate power. But because the films are colored, some light becomes reflected from the film surface. The result is a reduction in power generation capacity of around 10%. Compared with photovoltaic modules lacking decorative films, photovoltaic modules having such films with a wood-grain pattern (pictured below left) yield a power generation capacity of about 90%2; modules with monochrome green decorative films (pictured below right) have a power generation capacity of around 92%2. Thus, the reduction in power generation capacity varies according to the color and design of the film.

1-4. Uses for photovoltaic modules with decorative films

Decorative films can be produced in a great variety of colors, and so they can reproduce colors and design features to suit their surroundings. For example, lightweight photovoltaic modules with decorative films could be used for the walls of stores or buildings and on the outer panels of various vehicles. Photovoltaic sheets with decorative films could be applied to clothing, bags, outdoor goods, and others in innovative spaces.

2. Verification tests

As mentioned, the pigments used for decorative films were originally developed for automotive painting, and so they should have high durability and good design features. Toyota, NPAC, and F-WAVE have undertaken verification tests within the grounds of F-WAVE’s Kumamoto Factory. The aim is to assess the durability, power generation characteristics, and aesthetic harmony with surroundings in actual-use environments. From the findings of those tests, Toyota and NPAC intend to continue developing decorative films toward devising forms of solar power generation that fit their environment even more harmoniously.

| Verification test goals | Evaluating power generation characteristics, colorfastness, and other durability characteristics of photovoltaic modules with decorative films |

|---|---|

| Testing period | From March 12, 2021 to March, 2022 (Tentative) |

| Testing location | F-WAVE’s Kumamoto Factory |

| Photovoltaic modules used in the tests |

|

References

- 1

- T. Masuda et al., IEEE Journal of Photovoltaics 8 (5), 1326-1330, 2018

T. Masuda et al., Coatings 8 (8), 282, 2018 - 2

- Average values from multiple measurements

Related link:

Contact Information (about this article)

Frontier Research Center

- Email:

- xr-probot@mail.toyota.co.jp✉