Mobility

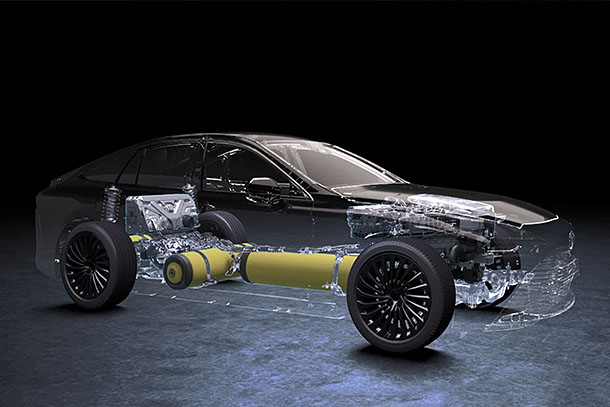

Toyota is shifting toward a "mobility company" in this once-in-a-century period of profound transformation. We are striving toward our goal of realizing the future mobility society. With an unceasing passion for beloved cars, we will remain committed to delivering ever-better cars to our customers.

LATEST UPDATES

- 2024/04/18

- "Land Cruiser" (Vehicle Gallery) updated