Section 1. The Inventions and Ideas of Sakichi Toyoda

Item 4. The Birth of Jidoka

Completed in 1897, the Toyoda Power Loom, Japan's first self-powered loom, drew acclaim for its ability to produce high quality cotton cloth in a stable manner, and gained widespread public attention.

The Toyoda Power Loom featured a weft halting device1 which automatically stopped the machine when the weft thread in the shuttle broke or was exhausted.

In power looms, if the weft or the warp thread breaks and the machine is not stopped immediately, faults can occur, such as the warp continuing to be incorporated into the fabric without the weft, or the broken warp thread being left out, leading to the output of damaged fabric. Sakichi Toyoda researched systems to prevent such faults, and in addition to the weft halting device mentioned above, also made several other inventions and improvements, including a system for maintaining a constant tension of the warp thread to prevent breakages, and a warp halting device to stop the loom when the warp thread broke.

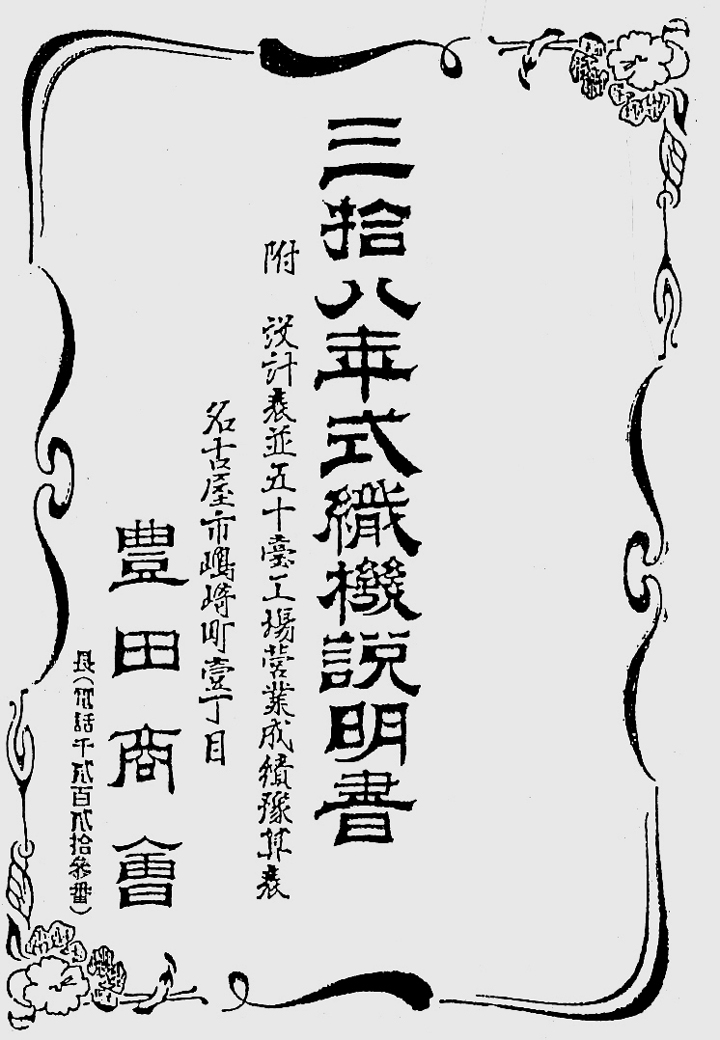

The Toyoda Power Loom released by Toyoda Shokai in 1905 was not an automatic loom, but a so-called "regular" power loom, and incorporated features such as those described above to prevent defects. According to the instruction manual2 for the Toyoda Power Loom, the following were the model's main features:

- 1.The warp tension controller automatically maintained the warp output at a constant tension. This resulted in less frequent breakage of the warp thread, reducing loom downtime and producing other benefits. In terms of product value, fabrics had a consistently fine texture and uniform quality.

- 2.The loom featured a warp halting device which automatically shut down the machine when the warp thread broke. This meant that the machine did not have to be constantly watched, allowing a single operator to run several looms at once. Also, quality defects such as missing or tangled threads decreased, reducing the likelihood of damage to the fabric.

- 3.A weft halting device halted the loom when the weft thread broke or ran out. As in item 2, this eliminated the need for the machine to be constantly watched.

Items 2 and 3 aimed to prevent loss and waste from quality flaws and reworking by automatically stopping the loom when irregularities occurred. Sakichi’s design concepts live on even today in the Toyota Production System as the origin of jidoka.3